HTS Maxon – Smartfire Intelligent Combustion Control System

Need help selecting your product?

The Honeywell Maxon SMARTFIRE® Intelligent Combustion Control System is an advanced closed-loop platform that optimizes combustion efficiency, safety, and repeatability across industrial burner systems. Combining continuous oxygen trim, real-time combustion monitoring, and intelligent valve actuation, SMARTFIRE® delivers highly accurate fuel-to-air ratio control, reduced emissions, and lower operating costs. Designed to integrate seamlessly with Honeywell Maxon burners and SMARTLINK® valve technology, SMARTFIRE® provides complete digital management of air and fuel delivery in modern thermal process systems.

Features & Benefits

- Continuous, closed-loop fuel-to-air ratio control for optimal combustion efficiency.

- Integrated O2 trim maintains precise excess air across varying process loads and ambient conditions.

- Combines the SMARTFIRE® controller, SMARTLINK® DS actuators, and intelligent valve assemblies into a unified system.

- Reduces setup and commissioning time through automated calibration and digital tuning.

- Built-in diagnostics, data logging, and communication interfaces support predictive maintenance and process optimization.

- Up to 8 channels of control available for multi-burner or zoned applications.

- Designed for integration with existing PLC and SCADA systems via Modbus TCP/IP or RTU protocols.

System Overview

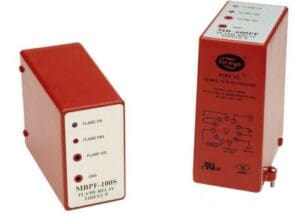

SMARTFIRE® consists of three primary system components:

| Component | Description | Key Features |

|---|---|---|

| SMARTFIRE® Controller | Core combustion control module | Manages all process inputs/outputs, air/fuel ratio, O2 trim, temperature, and safety interlocks. Communicates with field devices via Modbus TCP/IP or RTU. |

| SMARTLINK® DS Actuators | Digital positioners for valves/dampers | Provide precise digital valve control with feedback and diagnostics; eliminate mechanical linkages and manual tuning. |

| O2 Trim Sensor & Analyzer | Real-time oxygen feedback device | Continuously measures flue gas oxygen and adjusts the combustion profile for maximum efficiency and low emissions. |

Technical Specifications

- Control Type: Closed-loop, digital PID control with integrated O2 trim and air/fuel ratio management.

- Inputs: O2 analyzer, temperature, pressure, valve position, and user-defined process signals.

- Outputs: SMARTLINK® DS valve actuators, modulating dampers, safety interlocks, alarms, and data logs.

- Communication: Modbus TCP/IP or RTU for integration with PLC, SCADA, and DCS systems.

- Power Supply: 100–240 VAC, 50/60 Hz or 24 VDC (depending on configuration).

- Operating Range: Ambient −20°C to +60°C (−4°F to +140°F).

- Certifications: CE, UL, and CSA compliant for industrial combustion applications.

Applications

The SMARTFIRE® Intelligent Combustion Control System is designed for precision thermal process control and continuous efficiency management in:

- Industrial furnaces and kilns

- Boilers and process heaters

- Thermal oxidizers and incineration systems

- Heat treatment and metallurgical processes

- Food and chemical process heating systems

Documentation

- Data Sheet – Maxon SMARTFIRE® Intelligent Combustion Control System: specifications, configuration options, wiring details, and system integration guide.

Additional Information

- Combines combustion control, data acquisition, and valve actuation into a single digital ecosystem.

- Supports redundant communication and fail-safe shutdown options for critical process environments.

- Reduces maintenance and downtime with predictive fault detection and automated diagnostics.

- Compatible with Honeywell Maxon burners, SMARTLINK® DS actuators, and combustion monitoring systems.